Lithium Batteries – BMS

LITHIUM BATTERY BMS INSTALLATION

By Mark Smith

CEng, CMarEng, FIMarEST, BAppSc(MarEng) Engineering Surveyor Accredited Marine Surveyor: AMSA – 3242-6148 4 Qld EC lic. 73995

Based in Brisbane, Australia, Mark Smith is an AMSA Accredited Marine Surveyor, qualified electrician, and a Chartered Marine Engineer with over 40 years’ experience. Mark is a member of the Australasian Institute of Marine Surveyors, and Fellow of the Institute of Marine Engineering, Science and Technology (IMarEST). Mark is the owner of SET Maritime & Electrical, designer of the polarity testing device – ESHORE.

With the increasing use of lithium batteries within the maritime industry, every Surveyor is now seeing more and more of these types of installations during their surveys. The uptake is being driven by Suppliers spruiking all the advantages and ease of installation. However, not all lithium battery BMS configurations are compliant with the installation type being used. With the attending Surveyor noting a new lithium battery installation, this will warrant a closer examination for its safety compliance.

The DCV Surveyor needs to be able to look objectively at the advice and documentation given to them by the electrical installer for compliance of a lithium batteries for ELV and LV installation.

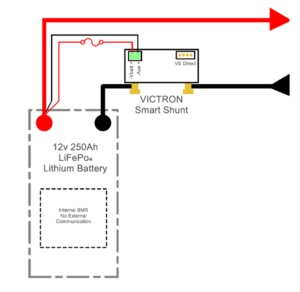

For example, the below circuit wiring (Fig: 1) is a system that was presented to me, and I was advised that the Supplier had said this was a compliant installation.

Fig: 1 – Proposed compliant system for battery monitoring

The suggestion was that the above configuration is compliant with NSCV and AS/NZS 3004.2, based upon the assumption that the internal BMS and the Smart Shunt are in communication. After consulting VICTRON, they have indicated that the fitting of a Smart Shunt does not meet the compliance requirements of the Standard for lithium batteries with internal BMS that has no communication ports.

This arrangement was then not approved, as it was not compliant for two reasons:

- Not meeting the requirement of the Standard, as the fitted BMS had no communication ports fitted to allow comms between such systems as power conversion equipment, charging systems, alarms, and cooling systems (if applicable).

- Outboard engine charging (alternator failure).

Note: Reference VICTRON Web page: Careful – Alternator Charging Lithium

https://www.victronenergy.com/blog/2019/10/07/careful-alternator-charging-lithium/

This is but one of the many areas in which a Surveyor needs to have sufficient knowledge to engage with the installer to determine the type of installation, and if the BMS meets its compliance for the configuration for the communication needed.

Generally, this information is available in online forums that provide guidance notices and/or factsheets. To date, I have not been able to locate any guidance notices and/or factsheets related to lithium battery installations that are useful to pass on for reference to Surveyors.

The purpose of this article is to start a discussion regarding lithium battery installations and to develop guidance notes to assist Surveyors when inspecting these installations.

Firstly, it is important to use as a baseline guide AS/NZS 3004.2, Section 2.9.3 – Additional requirements for lithium-ion batteries.. The following guidance notes that I used, may be helpful to others. This is not a definitive list by any means and is just a starting point to create a forum, to discuss and help Surveyors develop their own guidance notes. This will help in the survey process of identifying safety issues involving lithium batteries.

The following clauses in BLUE are from Section 2.9.3 of the Standard:

a) Lithium-ion batteries shall be installed in locations that ensure the battery manufacturer’s specified operating temperature limits cannot be exceeded and are appropriate for the IP rating of the battery and its management system.

Guidance Notes:

- Batteries of mixed chemistry are not to be stored in the same enclosure.

- Check the IP ratings for all systems (eg. Inverters are not generally rated for mounting in engine rooms).

b) Each lithium-ion battery shall be provided with a battery management safety system (BMS) either integrated into a battery pack or as a separate component located adjacent to the battery. The BMS shall continuously monitor the voltage and temperature of each cell in the battery.

Guidance Notes:

- The BMS is to monitor the voltage and temperature of each cell. This is typically not how these are monitored, as the cells are grouped into packs of 4, with this pack’s voltage being monitored and a single temperature probe is fitted to detect a rise in temperature within the casing (Fig: 2).

Fig: 2 – Typical internal arrangement for a Lithium Battery. (Courtesy of Sunbeam Systems)

- This arrangement does not fulfil the clause in the Standard that requires that the voltage and temperature of each cell are to be monitored. There are 2 observations to make for this battery-type BMS configuration for voltage and temperature monitoring:

i) Each cell is not monitored for voltage, but for a series of cells.

ii) Each cell is not monitored for temperature and only the internal moulded casing is monitored.

However, it may be reasonable to consider that if all is mounted within a moulded casing the lithium battery is compliant for a single battery 12V system only.

- The other problem that arises is when lithium batteries are placed in parallel or series, how will these batteries with internal BMS communicate with each other if not fitted with comms ports.

c) All charging sources shall be automatically disconnected by the BMS when voltage exceeds the manufacturer’s recommended maximum.

Guidance Notes:

- With a single charging source to a single 12V lithium battery, the internal BMS will meet some of the requirements with no communication ports.

- Internal BMS with no comms, does not provide an audible or visual alarm to external devices.

- A further problem here is if the batteries are in parallel or series, as when a battery shuts down due to a warning or fault. It should be able to communicate with other batteries and devices such as power conversion equipment, charging systems, alarms, and cooling systems.

- Lithium batteries generally require a DC/DC charger (reference VICTRON Web page: Careful – Alternator Charging Lithium).

d) All connected loads shall be automatically disconnected by the BMS when the voltage falls below the manufacturer’s recommended minimum.

Guidance Notes:

- See Guidance Notes clause c).

e) The battery shall be automatically disconnected by the BMS from all connected load and all charging sources when the temperature exceeds the manufacturer’s specified maximum.

Guidance Notes:

- See Guidance Notes clause c).

f) The BMS shall provide an audible and visual alarm at the normal vessel operating position before a disconnection event occurs.

Guidance Note:

- An internal BMS fitted without communication ports cannot provide an audible and visual alarm at the normal vessel operating position before a disconnection event occurs and is therefore NOT compliant.

g) Lithium-ion battery ventilation air flows shall be in accordance with the manufacturer’s requirements. If specific air flow data is not provided the requirements of Clauses 2.9.2.2 or 2.9.2.3 shall be applied.

NOTE: Care must be exercised when disabling charging sources to avoid the risk of elevated voltages that may damage the equipment.

Guidance Notes:

- Check adequate venting is available, as charging lithium batteries generates significant heat.

- Lithium batteries generally require a DC/DC charger (reference VICTRON Web page: Careful – Alternator Charging Lithium).

- An internal BMS fitted without communication ports cannot provide a signal to operate cooling systems.

A further important development to be aware of about BMS, is there has been a recent review of AS/NZS3004.2, concerning batteries with an internal BMS. It has been proposed to adopt the notion that communication can be a wired or wireless configuration. This reference to wireless is a direct pull out of the recently released AS/NZS 3001.2:2022 Electrical installations –Part 2: Connectable electrical installations – Clause 5.4.12.3.4.

Currently, the monitoring via Bluetooth conductivity to an app, means the following parameters of the State of Charge data are displayed:

- Battery voltage

- Battery current

- Power

The failure here is that these apps do not communicate with other devices to control shutdowns of battery banks, power conversion equipment, loads, charging and cooling systems or initiate BMS alarms.

This may be an appropriate system for land-based Recreational Vehicles, in that if it all goes wrong you can pull the car over to the side of the road and get out to watch it burn at a safe distance. However, a vessel at sea, if it all goes wrong, the last thing you want to do is to get off into the water and be reliant on lifesaving appliances, while you watch it burn.

An old seafarer’s adage is, “Always step up to lifesaving appliances and never step down”. That is to say that the last option is to get into the water. To avoid this option, warning alarms inform you of a problem before it becomes critical thereby allowing you to take corrective action or suppress fires before the situation gets out of hand.

SUMMARY

The issue highlighted is that batteries with an internal BMS and no communication ports fitted, cannot communicate with other batteries and devices such as power conversion equipment, charging systems, alarms, and cooling systems.

The fitting of a Smart Shunt will not overcome this problem, as it does not communicate with the BMS but operates independently of it and monitors the following State of Charge data:

- Battery voltage

- Battery current

- Power

- Aux input reading (starter battery, midpoint or temperature)

These above monitoring parameters do not fully cover the requirements as set out in the Standard for the BMS and do not allow for an alarm relay like the VICTRON BMV series hardware for example.

Therefore, a lithium battery with an internal BMS to effectively work must have communication capability with other batteries and devices such as power conversion equipment, charging systems, alarms, and cooling systems.

To provide further clarity, I have further referenced *AS/NZS 5139:2019 – Electrical installations — Safety of battery systems for use with power conversion equipment, to provide further clarification on this matter. From this Standard in Clause 1.3.16 (and I paraphrase):

BMS – Electronical system that monitors and manages a battery or battery systems electrical and thermal states enabling it to operate within its safe region for the particular battery. The BMS provides communication between the battery or battery system and the power control equipment and potentially other devices.

Quite simply, Lithium batteries with an internal BMS, that have no communication ports, do not provide the level of safety that is required for marine installations. Additionally, the use of Bluetooth-connected devices does not provide communication with other devices to control other batteries, power conversion equipment, loads, charging and cooling systems. Also, with the reliance upon an app that will turn off after the connected device (iPhone, iPad, etc) is power-down. Once the connected device is powered up again, it then requires user intervention to turn the app back on.

* Note: It is good practice when researching safety compliance standards to reference other Standards, Guidelines and/or Class Rules to provide additional clarity on clauses.